The main objective of Procurement Department is to procure goods and services designed to meet operational requirements of construction projects to meet project feasibility. Also procurement department installs procurement insurance policies to ensure their organisation operates with integrity. Purchase department plays a very crucial role in site progress as its their responsibility to make material delivered on site as per requirement, so as to avoid hindrances on project site. A part from that department registers the potential suppliers and acquire new vendors.

Sunday 16 August 2020

Construction Procurement: Work practices and procedures through client's eye.

I would like to thank my mentor Mr. Vikas Sawant sir for providing me the opportunity to work in Procurement Department in my Internship at JP Infra Pvt Ltd.

Subscribe to:

Posts (Atom)

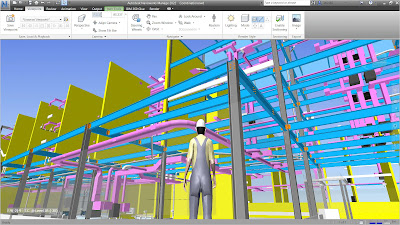

3 Simple Steps to Create 3D Walkthrough using Navisworks

3D Walkthrough is created for an exciting experience to showcase exact replica of project that will be created in future. Walkthrough movie ...

-

Waste-water relates to output source of water which we get from several activities like bathing, washing, using the toilet, outsource wate...

-

To become a Civil Engineer its very important to have a balance Theoretical Knowledge as well as Practical Knowledge. Eventually with the sa...