Syntax: =rept(string, number of times). Here number of times means the Repeat value of Character.

Thursday, 16 November 2017

Useful Commands of Advance Excel for its Optimum & Efficient Use

Syntax: =rept(string, number of times). Here number of times means the Repeat value of Character.

Sunday, 12 November 2017

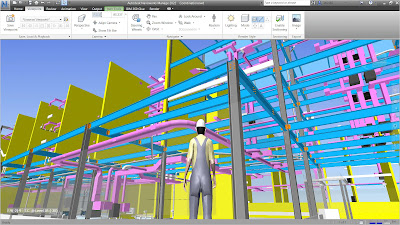

BIM- Building Information Modelling

Building Information Modelling (BIM) is a term coined to deal successfully with the problem of fragmentation & error in the process of building project creation till its implementation.

Building Information Modelling essentially means developing a system which can house or manage all of the information needed in a particular project in a single DATA REPOSITORY that could be accessed by all project participants and readily incorporated into all project documents

- Design Visualization & improved design communication

- Improve coordination & clash detection.

- Automates the quantity take of process.

- All building data at one place through data repository

- BIM allows energy analysis for sustainable design at early phase of design.

Friday, 18 August 2017

Vishwaniketan's Under Graduate Fellowship Program

Vishwaniketan’s Institute of Management Entrepreneurship & Engineering Technology (iMEET) is approved by All India Council for Technical Education (AICTE), New Delhi, HRD Ministry, and Government of India. It is affiliated to Mumbai University. The CTIF-Vishwaniketan network is responsible for our collaboration abroad and in India.

Vishwaniketan works with a vision to produced quality engineers who will positively impact there own life and also bussiness and society at large. Vishwaniketan focus on Project Based Learning approch to solve human and technology Problems. Vishwaniketan aim to create socially aware entrepreneurs who will empower society with relevant technology and business solution.

What is UG Fellowship Program of Vishwaniketan?

UG Fellowship Program is traning program which deals to pursue pratical and project based Learning in foregin universities. The best possible global exposure and learning provided to the student help them transform themselves into ideal global citizens .Vishwaniketan not only believe on this philosophy but ,has also taken major positive steps towards achieving this goal by implementing international programs with foreign universities.

Collaboration with foreign universities.

Vishwaniketan has collaboration with foregin universities throughout the globe. Vishwaniketan organise UG Fellowship Program for engineering students all over india which are been selected on the basis of their projects.

The universities which are collaborated with vishwaniketan are as follows:

1) Aalborg University, Denmark.

2) UNESCO chair on PBL.

3) Technical University of Sofia, Bulgaria.

4) Ural Federal University, Russia.

5) Stevens Institute of Technology, New Jersey-USA.

6) University of Rome-TorVergata, Italy.

7) Athens Information Technology, Greece.

8)National Technical University of, Ukraine "Kyiv Polytechnic Institute".

9)CTIF, Princeton University, USA.

10) Global ICT Standardisation Forum for India (GISFI).

11) Mae Fah Luang University, Thailand (TBC).

12) University of Cape Town, South Africa (TBC).

13) University of Arkansas, USA (TBC).

Selection Procedure of 2017

Selection Procedure for UG Fellowship Program

The selection process is been distributed in 5 steps as follow

Step1: Registration Process

In this step students should visit www.vishwaniketan.edu.in and register themself.

Step 2: Projects Completed by Past Batch

In this step the students should go through the project which are completed by last batch students. The projects completed by students are available on website.

Step 3: Projects offered

In this step the students should go through the projects offered by the foreign universities. This step is very important for students to go through the projects and select proper universities which are related to the projects which studentshave done in past.

Step 4: Improve your chances

Vishwaniketan also offers traning of softwares for students in january under their VAP program. This will help student to have efficiency and fast complition of project.

Step 5: Interviews

In this process the selection committee will call students for interviews which will be based on their projects done in past as well as in indentifying the qualities and skills which are required for UG FELLOWSHIP.

The students should Carry Hard Copies of

1)Application Form (Emailed at ugfellowship@vishwaniketan.edu.in).

2) Two Copies of Latest Resume.

3) Statement of Purpose(SOP).

4)Passport Copy (if Available).

5)List of Projects Done so far.

6)Broad areas you wish to work.

Note the interview for long distance students are conducted on Skype.

Contact Information.

Address

Survey No-52 Off Mumbai-Pune Expressway Kumbhivali, Tal- Khalapur,Maharashtra 410203.

Phone: (02192) 274206/274207/274208/274210

Email: director@vishwaniketan.edu.in

Email: ugfellowship@vishwaniketan.edu.in

Friday, 28 July 2017

The Indian Rupee Will Make you feel Rich.

Every one has a dream to go abroad and explore world but most of us eliminate the idea by the fear of cost. But here are some countries where Indian currency will make you rich.

These countries are also the best option for us to have start-up industries or to have Indian owned Multinational Companies Branches in these countries.

1) Bolivia: 1 Bolivian Boliviano = 9.28 Indian Rupee.

2) Paraguay : 1 INR = 74.26 Guarani.

3) Zimbabwe: 1 INR = 5.85 ZWD.

4) Costa Rica : 1 INR = 8.15 Colons.

5) Belarus : 1 INR = 216 Ruble.

6) Cambodia : 1 INR = 63.93 Riel.

7) Vietnam : 1 INR = 338.35 Dong.

8) Mongolia : 1 INR = 29.83 Tugrik.

9) Hungary : 1 INR = 4.22 Forint.

10) Nepal : 1 INR = 1.6 Nepalese Rupee.

11) Sri Lanka : 1 INR = 2.08 Sri Lankan Rupee.

12) Algeria : 1 INR = 1.63 Algerian Dinars.

13) Indonesia: 1 INR = 197 Indonesian Rupiah.

14) Japan: 1 INR = 1.73 Japanese Yen.

15) Iceland: 1INR = 1.72 Icelandic Krona.

16) Chile: 1INR = approximately 10 Chilean Peso.

17) Uzbekistan: 1INR = 44.76 Uzbekistani Som.

18) Djibouti: 1INR = 2.65 Djiboutian Franc.

19) Yemen: 1INR = 3.74 Yemeni Rial.

20) South Korea : 1 INR = 16.52 South Korean Won.

21) Laos 1 INR = 120.35 Laotian Kip.

Indian Currency may be less as compared to the currency of developed nations like USA and UK but Indian currency is far more rich currency in many countries of world as stated above.

We can not only choose the above stated countries for our holidays but also can setup industries in these countries in low amount. However there are some factors that are to be taken into consideration before setting up industries in these countries.

Wednesday, 28 June 2017

Visit to Precast concrete Industry in Yekaterinburg.

The first industrial visit was organised by Ural Federal University for UG Fellowship students.The visit was organised at Precast Concrete Factory named "ATOMSTROI KOMPLEX" in Yekaterinburg. The company was set up in Yekaterinburg 13 years ago.

The first step of making Precast concrete blocks is bringing the raw materials and mixing them in a mixer according to its requirements. The raw materials used are Gypsum lime cement ash or pfa and aluminum.

These raw materials are brought and placed in mixers according to requirement of concrete block material design. After the mixing process hardening of concrete takes place.

The operator operates the whole process with the help of an software shown in fig.

After the mixing process and hardening process is over we get the concrete block as shown in figure.

After this process the concrete block is tilted with 90 degree angel just to make cutting procedure easier.

After the tilting procedure is done the block is taken to 3 steps cutting procedure where the concrete block is cut as per the requirement.

In first step the block goes through horizontal cutting process.

In second step the concrete block undergoes with vertical cutting process.

In third step the concrete block undergoes with cutting blocks as per required dimension the extra concrete is again send for its reuse process.

Then the cake is send to Autoclave for final hardening of the blocks. The Autoclave is 37m wide and the blocks are kept for 12 hours at 120 to 180 degree Celsius.

After 12 hours the block are taken out of Autoclave and then are send to wrapping sections were the blocks are wrapped with help of machines to save the blocks from rain and sort of stuffs.

The company has the ability to make Precast slabs as well as Precast stairs. The company works throughout the day with certain shifts.

Thursday, 15 June 2017

Design Of Steel Structures with Russian Standards

Their are basically 5 steps of design in Russian system

1) Development of Design scheme.

2) Determination of Loads.

3) Calculation of Internal forces in Elements.

4) Selection of Cross Section.

5) Check for Designed Cross Section.

Loads & Loads Combination

INDIAN CODES :-

•) In India the Calculation of Dead load, Live Load & Wind load are done with reference of IS 875.

•) The Specialized Information of Industrial Buildings is provided by some codes like

IS 807.

•) For Design of Earthquake Loads in India the reference of IS 1893 is taken into consideration.

•) For Design of Towers & Other Forms of Structure the codes taken into consideration are IS 802, IS 9178, IS 6533.

RUSSIAN CODES :-

The Basic data on all types of loads except the earthquake loads are given in SP20.13300.2011 loads and effects code.

For Design of Earthquake loads or Sesmic Loads SP14.13330.2011 is taken into consideration.

Loads & Effects

In Russian Standards all the loads are divided in two groups depending upon its duration and action.

1) Dead Load (Permanent): It includes the weight of Structures, Weight of Soil & pressure for underground soils, forces from prestress.

2) Live Load (Temporary): These loads are further divided into two sub category

2.a) Long Time loads like Store goods, machines in industrial Buildings, Pressure of Fluids Etc.

2.b) Short Time loads like Weight of People, Weight of Snow & Wind loads.

There is one special category designed for Earthquake loads and loads caused due to sudden breaches of technological process.

The load has two values-

a) Unfactored Load &

b) Design Load.

Unfactored Load ie Specified Characteristic Load are the loads that acts on structure during its operation.

Design Loads are the maximum possible loads that can act on structure.

Formula- P = P^n × (gamma)f

Where P. = Design Load

P^n. = Unfactored Load

(gamma)f = Partial Safety Factor for loads

given in SP 20.13330.2011

(gamma)f = 1.05 For weight of steel.

(gamma)f = 1.04 For weight of Snow.

The reability coefficient for load shows how many times the design load may exceed Unfactored load.

Monday, 8 May 2017

VISIT EXPERIENCE AT WATER TREATMENT PLANT.

To become a Civil Engineer its very important to have a balance Theoretical Knowledge as well as Practical Knowledge. Eventually with the same concept our visit was organized to WATER TREATMENT PLANT at Nigdi.

The visit was plan with the intention to enhance our theoretical knowledge with practical experience.

The Water Treatment Plant is operated by Pimpri-Chinchwad Municipal Corporation (PCMC). Water is treated here and then supplied to the entire twin city.

The Water Treatment Plant works with basic aim to make water more acceptable for a specific end-use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment.

The Operation Cycle of Water Treatment Plant.

The Water Treatment Plant work is distributed in 6 parts.

1) Intake source management to get fullfill amount of water every day.

2) Sampling Unit.

3) Processing Unit.

4) Storage unit.

5) Supervision & Control Unit.

6) Maintenance Unit.

The Intake Source

The intake source of Water Treatment Plant plays a very important role as the intake source should be sufficient to provide every day water requirement of Plant so as to avoid shortage of water.

The Intake Source of Water treatment Plant Nigadi is Pawna dam situated nearly 4km away from the plant. The plant treats 420 MLD ( ie Milions Litres Per Day).

PCMC is planning to build fourth water treatment plant in Chikhali.The new plant will enable the PCMC to treat water that will be drawn in future from Andra and Bhama Askhed dams to meet the growing needs of Pimpri Chinchwad.

The city's population is expected to rise to 25 lakh by 2025, which means the water supplied through Pavana dam will prove inadequate. As per the plan, the areas in Pavana and Mula river basins will get water drawn from Pavana dam while the areas in the Indrayani river basin will get water from Bhama Askhed and Andra dams, located around 20 kms away. From reports for Pimpri Chinchwad, the state government has sanctioned 167 MLD water from Bhama Askhed and 100 MLD water from Andra dam.

Laboratory Treatments

The water sample from source is been treated to examine the amount of contaminants and the selection of the suitable procedure of treatment.

The is managed by Mr. Sanket Mote and he guided us with the procedure conducted at the plant.

The test conducted are:

•)Turbidity

•)pH

•)Hardness

•)Heavy metals concentration

Turbidity test is conducted to determine the amount of mud silt and other containments in water which cant be seen through naked eyes.

Turbidity is generally high in Rainy season as compared to other season therefore extra efforts are taken at the time of Rainy season.

Turbidity can be measured using either by an electronic turbidity meter or a turbidity tube. Turbidity is usually measured in Nephelometric turbidity units (NTU) or Jackson turbidity units (JTLJ),

depending on the method used for measurement. The two units are roughly equal. At Water treatment Plant the Turbidity is measured by Turbidity Meter

HACK2100QT.

Drinking water should have a turbidity of 5 NTU/JTU or less. Turbidity of more than 5 NTU/JTU would be noticed by users and may cause rejection of the supply. Where water is chlorinated, turbidity should be less than 5 NTU/JTU and preferably less than 1 NTU/JTU for chlorination to be effective

The dosage for alum to form coagulant is determined and added after aeration to for proper sedimentation. However if the amount of coagulant is more then it affects the filtration process.

Bacterial Test

The bacterial test is conducted to determine the Pathogenic bacteria's present in the sample.

There are some types of bacterial test like

1. MPN method.

2. Radicals.

3. Single path method.

The Equipment used to conduct Bacterial test at Water treatment Plant Nigdi was Single path kit for the 3rd method.

The aim of conducting the bacterial tests determine the Pathogenic bacteria's present in the sample so as to determine the amount of Chlorine dosage for bacterial degradation of water is designed.

Residual Chlorine Test.

The Residual Chlorine test is to determine the quantity of residual chlorine in the sample to preserve the quality of water supplied

Orthotolidine Test

In this test, 10 ml of chlorinated sample of water is taken after the required contact period, in a glass tube. To this 0.1 ml of orthotolidine solution is added. The color formed is observed after 5 minutes. The formation of yellow color normally indicates the presence of chlorine (either combined or free) in the water. The more yellow the color, the greater, is the chlorine residual. The amount of residual chlorine can be ascertained by comparing the colour developed in the glass tube with the standard colors already kept in the laboratory. This test, is therefore, very simple and does not require much technique or time. Under normal conditions, a lemon yellow color is satisfactory for public water supply. The orthotolidine test will normally gives the total residual chlorine present in water. However, it may be adjusted so as to give separately the quantities of free residual as well as combined residual of chlorine.

The free residual chlorine forms the yellow color during the first 5 seconds of the addition of orthotolidine, while the combined residual chlorine goes on forming the colour for about 5 minutes. Hence, the colour after 5 seconds will give the quantity of free residual chlorine, and the colour after 5 minutes will give the free and combined chlorine. The difference in value between the two values is the combined chlorine.

The orthotolidine test, however, is not accurate, because the impurities such as iron, manganese, nitrate etc., are likely to cause a false yellow colour, and indicating wrong and increased chlorine residual.

Aeriation unit

This is the starting unit of the water treatment procedure. Once the sample is tested the water coming from Ravet is pumped through this cascaded aerator. The purpose of having an aerator is to improve the amount of dissolved oxygen in the water and to release the other gases, also a few metals get oxidized during this procedure.

This procedure is important to make the water odorless as there is transmission of gases during this process. Water is allowed to freely fall on the cascaded steps and which each fall the water particles are exposed to the fresh air from the surrounding. This process promotes the exchange of gases like CO2, etc.

Clariflocculator

This is the second unit placed after Aeration unit.

flocculation is the central portion of the tank which consist of a mixer that is rotating at a low speed to facilitate the collision of the charged particles and their conversion into sludge which are settled down.

The water contains negatively charged particles whose amount is been analyzed and the same quantity of positive charged particles are supplied in so as the positive charged particles and negative charged particles gets attracted to each other and as the size of this particles increases they settled down in Sedimentation zone.

Sedimentation zone is the outer zone which is curved in nature and there is depression at the center.

The water is having a detention time of 0.5hr in the flocculation and 3hr in the sedimentation zone.

Chlorination Unit

Chlorine is used to destroy disease-causing organisms in water, an essential step in delivering safe

drinking water and protecting public health. Chlorine is by far the most commonly used disinfectant

in all regions of the world. Where widely adopted, chlorine has helped to virtually eliminate water-

borne diseases such as cholera, typhoid and dysentery. Chlorine also eliminates slime bacteria, molds

and algae that commonly grow in water supply reservoirs, on the walls of water mains and in storage

tanks. Only chlorine-based disinfectants leave a beneficial “residual” level that remains in treated

water, helping to protect it during distribution and storage.

Chlorine is a versatile and low-cost disinfectant appropriate for any size water system, whether it

serves a remote rural village or a large modern city. Where piped water supplies are not available,

chlorine can also be used for treating water in individual households. Specially-packaged chlorine

bleach can disinfect household water.

However there are other disinfectants too like UV, Ozone, Boiling, Potassium Permaganet. But the main objective of adding disinfectant to water is to provide safe drinking water till it reach large span consumers. Therefore chlorine is the best option which satisfy all the requirements.

Storage unit and pumping

In this unit the treated water is allowed to stay for sometime and them pumped to the distribution network by using mechanically operated pumps. The plant is powered by electricity from the MSEDCL

Filtration unit

This is a big unit comprising of a number of filter pits. The filter used in this tank was rapid sand filter in which the water is allowed to pass through the sand and it gets filtered as it passes down under the action of gravity. The sand is having small pores which allows water to pass through it preventing the suspended matter.

During filtration the water enters the filter through upper valve, moves down towards the filter bed, flows through the filter bed, passes the underdrainage system (filter bottom)and flows out through lower valve. The unit used to measure filtration rate is actually the approach velocity, which is the inflow rate (m^3/h) divided by the filtration area (m^2).

When, after a period of operation, the filter rate controller is fully opened, further

clogging of the filter bed cannot be further compensated and the filtration rate will fall.

The filter is then taken out of service for backwashing.

For this, the upper and lower valves closed, and upper back wash valve is opened to drain the remaining raw water out of the filter. A few minutes later lower backwash valve is opened to admit the wash water.

The backwash rate should be high enough to expand the filter bed by about 20% so that the filter grains can be scoured, and the accumulated deposits carried away with the wash water. The wash water is collected in the wash water troughs from where it drains to waste. When the backwashing is completed, backwash valves are closed and upper valve is re-opened, admitting raw water to begin a new filter run.

Use of Supervisory Control and Data acquisition (SCADA)

This plant employs one of the most advanced techniques for its daily operations. SCADA is a cloud based tool that is developed for the plant and helps the plant management to monitor and control the daily activities at the plant in the supply network.

Diagram Explaination

Level 0 contains the field devices such as flow and temperature sensors, and final control elements, such as control valves.

Level 1 contains the industrialised input/output (I/O) modules, and their associated distributed electronic processors.

Level 2 contains the supervisory computers, which collate information from processor nodes on the system, and provide the operator control screens.

Level 3 is the production control level, which does not directly control the process, but is concerned with monitoring production and targets.

Level 4 is the production scheduling level.

I would like to thank Civil Department of Trinity College of Engineering for conducting the visit to Water Treatment Plant Nigadi. Especially Meenakshi Khapre mam & Harshal sir for conducting the visit.

I would also like to thank

Mr. Praveen Ladkat Executive Engineer, PCMC for allowing us to visit the plant and to grab the pratical experience.

Thursday, 27 April 2017

SCUBA DIVING JOURNEY

1 Maharashtra Naval Unit NCC, Mumbai conducted the SCUBA Diving Camp 2014-15 at Command Swimming Pool of the Western Naval Command, Mumbai for the cadets representing all the seven Groups of Maharashtra Directorate. They are Mumbai ‘A’ and ‘B’ Group, Pune Group, Amravati Group, Kolhapur Group, Nagpur Group and Aurangabad Group. This camp includes cadets from Navy, Army and Air Wing from various parts of Maharashtra.

The Main Objectives of Camp :-

•) To expose NCC cadets to SCUBA Diving and Survival at Sea.

•)To build confidence amongst participants to voluntarily undertake waterborne rescue operations like flood relief, natural calamities etc when need arises.

•)To inculcate the spirit of adventure, camaraderie, character building, team work and ability to willingly face adverse conditions & hardships together.

•)To enjoy underwater flora and fauna.

•)To expose cadets to take up diving as a career option.

Camp Selection:

Western Naval Command has extended all facilities for conducting this camp at the Command Swimming pool located in Navy Nagar, Colaba. The Command Clearance Diving Team (Mumbai) has provided Diving equipment and Diving instructors to conduct the camp in both theory and practical classes on Diving. The camp was conducted from 06 Jul to 12 Jul 2014 which included swimming, medical and physical fitness tests. A total of 50 Cadets – 18 Girls and 32 Boys participated in screening and selection, out of which 30 cadets – 10 Girls and 20 Boys were selected for phase II training (which includes the actual exposure to SCUBA Diving) from13 Jul to 26 Jul 2014

Phase 1: Selection Procedure

The selection procedure was divided in 3 parts-

a) Ground Test.

b) Swimming Test.

c) Medical Test.

Ground Test was conducted at Kholi Stadium at South Coloba in south Mumbai.

The Test includes

1) 2km Run

2) 20 Push Ups (2 sets)

3) 15 Pull ups (2 sets)

Swimming Test was conducted at COMMAND SWIMMING POOL Colocated with Kholi Stadium in South Mumbai.

The swimming test Include a 400m Swim with the time limit of 4 min.

The final test was Medical Test was conducted in INS ASWINI HOSPITAL situated in South colaba. The test was divided in 4 parts.

1) ECG Test.

2) Chest xray test.

3) Ear Audioable test.

4) Chamber test.

The test were conducted to know the potential of cadets whtheir they are physically fit for the traning of Scuba diving.

The day used to start with a 2 km run in kholi stadium. Further we used to deal with ground exercise for next 2 hours.

After ending up with ground sessions for 3 hours. we were granted a break of 10 min.

Then we were taken to the Command Swimming pool and were granted traning on use of scuba diving equipments.

We had traning sessions on using the mask and snorkel.Further we learned the use of fins.

After sucessfully learning use of mask,snorkel and fins. we had a session on how to wear scuba diving equipments in short span. This was the most important session in scuba diving.

Next session was on how to communicate with diver through bells. This communication network in language of bells (ie a Nylon rope tied to shoulder on which is pulled and streched to communicate known as bell). We also had the jump session from 15fts approx.

Also in the evening we had lectures on different topics related to Defence.

On the second last day of camp all the cadets were taken to Naval dockyard to visit the Indian Naval Ship Trishul. It was a great experience to visit the dockward to see the different types of ships, Submarines etc. We were lucky enough to see the Ins Virat Standing in Mumbai Dockyard.

We had sessions on How the Radar system, Sonar System works. We also had sessions on how to circulate within the ship with the help of maps. We also visited the control room of ship from where the ship is been operated.

It was really a great experience to live the navy life at such a young age. I am fortunate to be the part of Scuba diving camp.

3 Simple Steps to Create 3D Walkthrough using Navisworks

3D Walkthrough is created for an exciting experience to showcase exact replica of project that will be created in future. Walkthrough movie ...

-

Waste-water relates to output source of water which we get from several activities like bathing, washing, using the toilet, outsource wate...

-

To become a Civil Engineer its very important to have a balance Theoretical Knowledge as well as Practical Knowledge. Eventually with the sa...