The first industrial visit was organised by Ural Federal University for UG Fellowship students.The visit was organised at Precast Concrete Factory named "ATOMSTROI KOMPLEX" in Yekaterinburg. The company was set up in Yekaterinburg 13 years ago.

The first step of making Precast concrete blocks is bringing the raw materials and mixing them in a mixer according to its requirements. The raw materials used are Gypsum lime cement ash or pfa and aluminum.

These raw materials are brought and placed in mixers according to requirement of concrete block material design. After the mixing process hardening of concrete takes place.

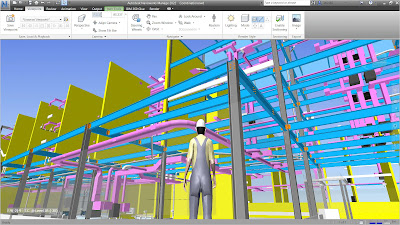

The operator operates the whole process with the help of an software shown in fig.

After the mixing process and hardening process is over we get the concrete block as shown in figure.

After this process the concrete block is tilted with 90 degree angel just to make cutting procedure easier.

After the tilting procedure is done the block is taken to 3 steps cutting procedure where the concrete block is cut as per the requirement.

In first step the block goes through horizontal cutting process.

In second step the concrete block undergoes with vertical cutting process.

In third step the concrete block undergoes with cutting blocks as per required dimension the extra concrete is again send for its reuse process.

Then the cake is send to Autoclave for final hardening of the blocks. The Autoclave is 37m wide and the blocks are kept for 12 hours at 120 to 180 degree Celsius.

After 12 hours the block are taken out of Autoclave and then are send to wrapping sections were the blocks are wrapped with help of machines to save the blocks from rain and sort of stuffs.

The company has the ability to make Precast slabs as well as Precast stairs. The company works throughout the day with certain shifts.

Welldone...

ReplyDelete